XLPE insulated power cable adopts chemical or physical methods to change the molecular structure of polyethylene from linear molecular structure to three-dimensional network structure, from thermoplastic polyethylene to thermosetting XLPE, so as to improve the aging resistance, mechanical properties and environmental resistance of polyethylene, and maintain excellent electrical properties. The parameters of 35kV Power cable are sorted out according to the samples of manufacturers for your reference.

1. Features and models:

The rated power frequency voltage uo / u is 21 / 35kV and 26 / 35kV.

Maximum allowable working temperature of cable conductor: 90 ℃

The maximum temperature of cable conductor shall not exceed 250 ℃ in case of short circuit (the longest time shall not exceed 5S)

The ambient temperature should not be lower than 0 ℃ during cable laying

Cable bending radius: three core cable shall not be less than 15 times of cable outer diameter; single core cable shall not be less than 20 times of cable outer diameter.

Class a system - when any phase conductor of the system contacts with the earth and the earth conductor, it can be separated from the system within 1min

Class B system - this kind of system only includes the condition of short-term operation of single-phase ground fault, and the time of ground fault shall not exceed 1H, but in any case, the longest time shall not exceed 8h, and the total duration of ground fault shall not exceed 125h per year;

Class C System -- a system that does not belong to class A or class B.

2. Cable structure diagram:

3. Cable structure size and recommended parameters:

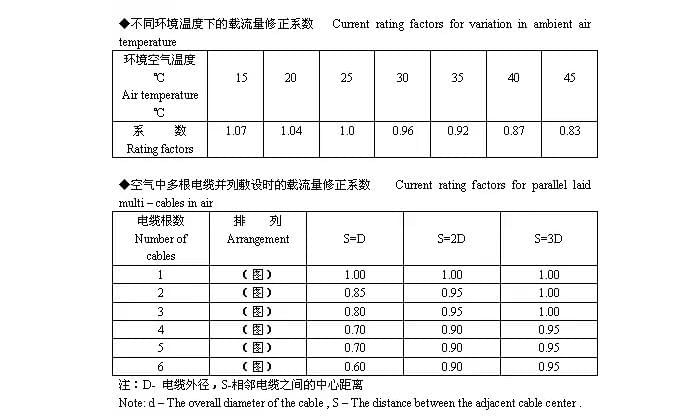

Cable ampacity:

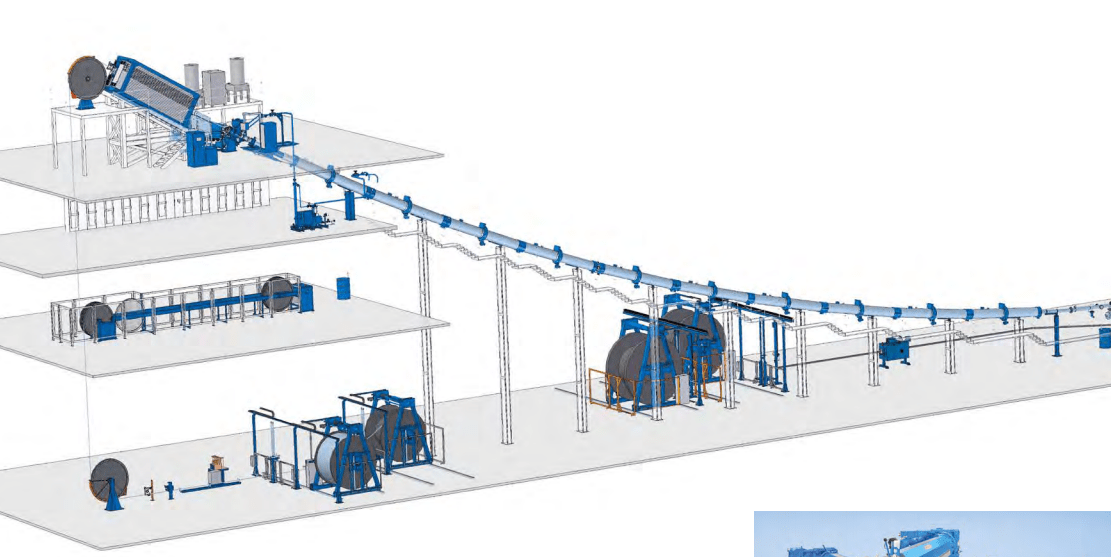

4. 35kv cable machine demand:

If you have cable knowledge to share, welcome to discuss with Max Xu:

+8618606615951