With the development of cable industry, the world economy is closely linked, and more and more countries vigorously develop their own infrastructure. Infrastructure needs a lot of communication equipment, and cable is one of them, and the development of cable is one of the national strategies. We are ready to invest a lot in building our own factories to meet the needs of domestic economic development.

The construction of cable factory is a very professional planning, in addition to the land, the plant also needs a lot of mechanical equipment, such as wire stranding machine, wire extrusion machine,wire drawing machine, etc., at the same time, professional technical personnel, very time consuming.

If you are going to build a factory, what steps do you need? Beyde company has many years of factory building experience, we will explain the whole process in detail.

1.understand the types of wires you want to produce, such as high-voltage cable, medium voltage cable, low-voltage cable, etc. Among them, the scope of low-voltage cable is very wide, but you need to plan the factory to produce all low-voltage cables, which requires a huge investment and a large risk. So you have to work with your technical staff to study the product range that suits you, and carefully study the sales situation of the market.provide the cable size list to supplier.

eg. Target product range:

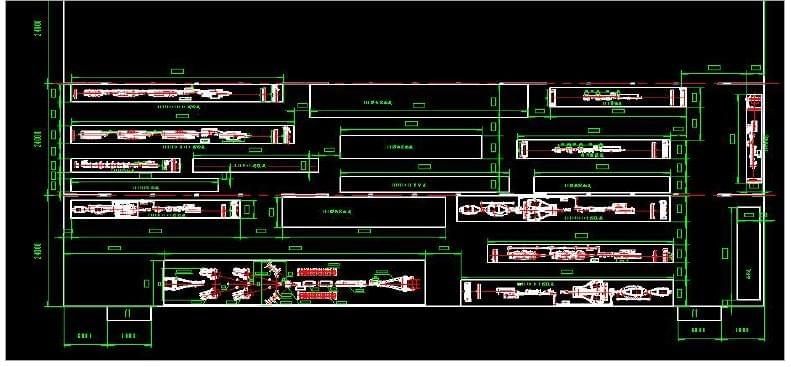

(1).BV wire range : From 0.75mm² to 240mm²

(2).BVR wire range : From 0.75mm² to 240mm²

(3).RVV wire range: From 3x0.75mm² to 3x 240mm²

(4).YJV wire range: From (3x10mm²+1x6²) to (3x240mm²+1x120mm²).

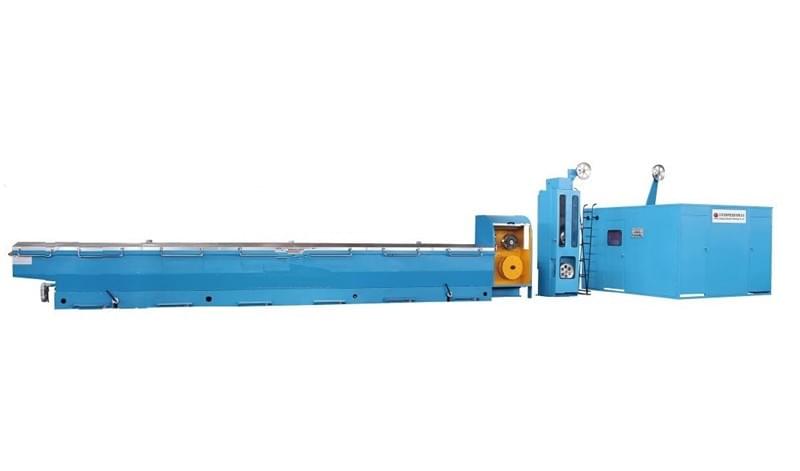

2.according to the requirements of the production cable model, list the equipment to be purchased. (1) if you have only copper rod, you need to purchase a wire drawing machine. The wire drawing machine adopts large, medium and small wire drawing machines according to the size of copper rod.

3. If you purchase copper wire and aluminum wire, you can meet the requirements of production as long as you purchase stranding machine. The stranding equipment can be divided into the following categories:(1). Rigid strander for twisting bare copper & aluminum wire

(2).laying up machine for lay-up fuction, twisting insulated wire.

(3).Tubular strander for twisting copper,aluminum and steel wire. high speed and improve production capacity.

(4).planetary strander is for twisting insulate wire and insulated wire too.

(5).cable drum twister is for large cross-section wire, the speed is faster than laying-up machine.

Customers purchase different equipment according to their own needs.

4. Extruder for producing insulating sheath.This product can produce inner and outer insulating layers, or directly achieve the function of three-layer co extrusion.

5. Provide the plane drawings of the construction plant to the machinery supplier. The supplier shall draw the placement position of all machines according to the list of required machines, and send the drawings to the guests for confirmation. After confirmation, the construction company shall build workshop and other relevant facilities according to the drawings, including power supply, gas source, etc., and then send them to the supplier for confirmation.

6. Confirm the order, the factory is responsible for production and transportation, and send the machine to the customer's factory, the factory sends technical personnel to the factory for installation, commissioning, operation test, staff training, etc. Make sure all machines are running perfectly. The machine supplier will provide the whole process of technical guidance and equipment maintenance.

7. All things need to be negotiated and trusted by both the supplier and the demander, so as to work together for the production of the new factory.