- Service

- …

- Service

- Service

- …

- Service

Power Cable Extrusion Line

Efficient cable production extruders for a wide range of materials.

Our extruders are high-performance machines for cable insulation and cable jacketing

Are you looking for a cable & wire manufacturing solution?

Please send us requests for quotation. Alternatively you can speak to our engineer by emailing or giving a call.

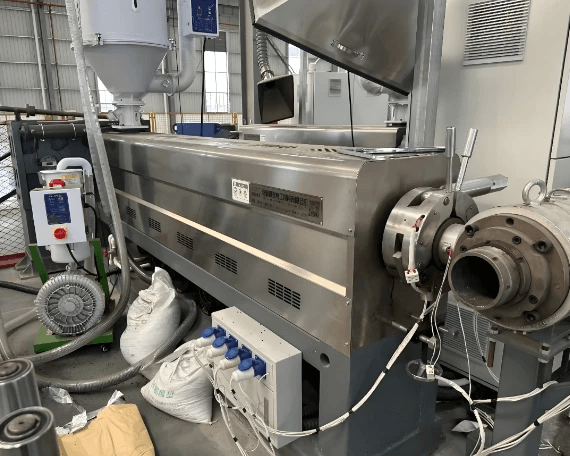

SJ200+120 Power Cable Jacket Extrusion Line

Our power cable jacket extrusion line is specifcally designed for high-voltage cable sheathing and extrusion requirements. Our 200mm and 120mm twin-screw extruder machines delivers exceptional performance, ensuring precise and efficient cable sheathing, applicable for PVC, PE, LDZH, LDLH semi-conductor PVC, semi-conductor PE.and so on.

SJ30 To SJ200 High Performance Plastic Extrusion Line

At BEYDE, we take pride in offering the high-performance plastic extrusion line specifcally designed for cable insulation and sheathing, covering LV to EHV power cable.

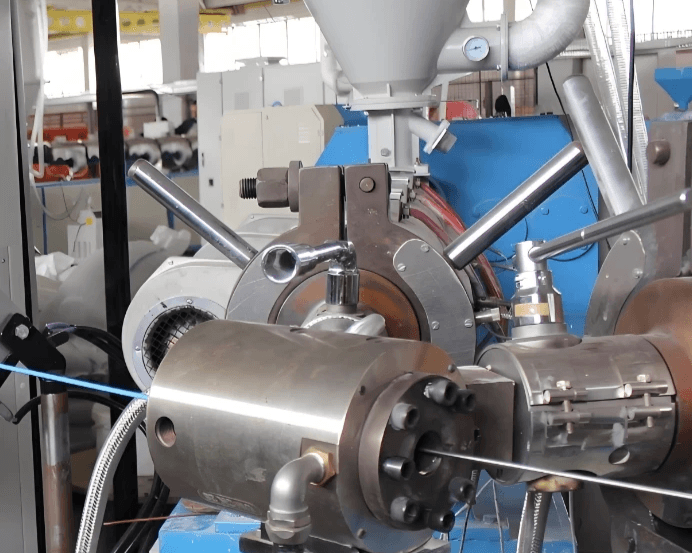

1 To 10 KV Crosslink Insulation Extrusion Line

The one-step silicon crosslink insulation extrusion line is designed for the insulation extrusion of cooper and aluminum conductors. Our crosslinki nsulation extrusion line is suitable for power cables ranging from 1kV to 10kV, overhead conductors, plastic cables and etc.

Applicable materials include PVC, PE and XLPE.

Enhance Your Cable Sheathing Process with Our Power Cable Jacket Extrusion Line

Increased Extrusion 0utput:

The plastic extrusion lineout performs conventional extrusion lines, providing a 30% higher extrusion volume and increased line speed.

Unigue Output Flow Design:

Unigue Output Flow Design:

Our extrusion line in corporates aspecially designed output flow channel. ensuring high-quality extrusion with an arc-shaped screw design.

Advanced Air Control System:

The control system combinesan industrial computer and Siemens S7 series control.enabling synchronized control and standalone

operation.

Comprehensive Control System:

The control system combinesan industrial computer and Siemens S7 series control.enabling synchronized control and standalone

operation.

Human-Machine lnterface:

The control system combinesan industrial computer and Siemens S7 series control.enabling synchronized control and standalone

operation.

High-Quality Materials:

High-Quality Materials: The main barrel and screw are made of 38GrMoA steel, treated with nitrogen for high hardness, wear resistance, and corrosion resistance.

Power Cable Making Equipments

Details Components of Power Production Line

PN1250 to PN3150 Pay-off Machine

- Pneumatic mechanical tension control for smooth payout.

- Proximity switch-based metering and wire break detection.

500kg to 5000kg Caterpillar Haul Off Unit

- Pneumatic clamping and automatic tensioning of the traction belt ensure low noise and high output effciency.

- Synchronization of traction speed with extruder speed ensures reliable andstable operation.

- The twin tracks are driven by a DC motor via a spiral bevel gear system, ensuring excellent control and performance.

- The pneumatic clamping and release system offers sensitivity and reliability. featuring a pressure adjustment display instrument.

PN1250 to PN3150 Take-up Machine

- Motorized wire clamping with mechanical and electrical protection mechanisms

- Easy loading and unloading ofwire bobbins

- Synchronization with the main machine for continuous tension during operation and delayed stopafter machine shutdown.

Get in Touch

More Power Cable Extruder, Please Drop Your Message

© 2019 Right: Beyde technology design